+44 (0) 1709 377147 | CONTACT US | About Prospec | Book your CPD | Request Brochure | International | Terms & Conditions

Lockers|

Case Studies|

Irvine Leisure Centre

Irvine’s new £18m sport and leisure facility, The Portal, ran jointly by KA Leisure and North Ayrshire Council, is located directly in the heart of Irvine, UK. This modernistic centre contains a 25m six lane pool which is considered the main attraction at The Portal, a training pool for infants, a smaller pool, a gym, and multipurpose sports hall which accommodates for a variety of sports such as football, basketball, and badminton. The new centre provides for exhibitions, public and social events, as well as sporting and leisure activities. Read MoreScarborough Sports Village

Opening to the public in June 2017 after 19 months of hard work, Scarborough Sports Village replaces both Scarborough Pool and Scarborough Sports Centre to create a modern, compact (all-in-one) centre. Architects Faulkner Browns were the starting point of this project, with main contractors Willmott Dixon being awarded this Design and Build contract, and Everyone Active, the centre’s leisure operator... Read More

News|

Introducing the Sprint City Cubicles Range

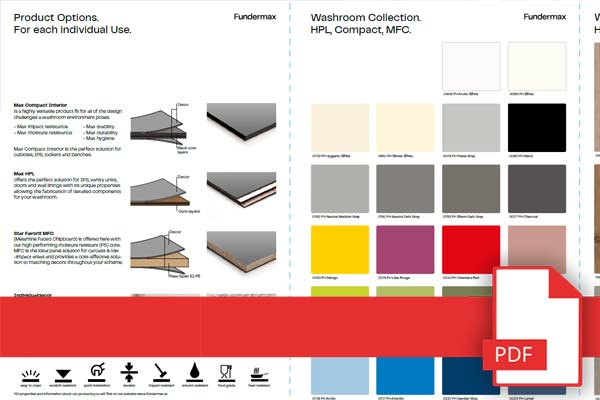

Prospec have recently launched the Sprint City cubicles range featuring 40mm HPL faced Chipboard with a Flush Front, rebated mating style, aluminium headrails and feet ensure the cubicle stands strong and rigid.

Maintenance|

Maintenance

For spare parts and maintenance please call 01709 377147 option 1 or email us at maintenance@prospec.co.uk